ComfortScale™

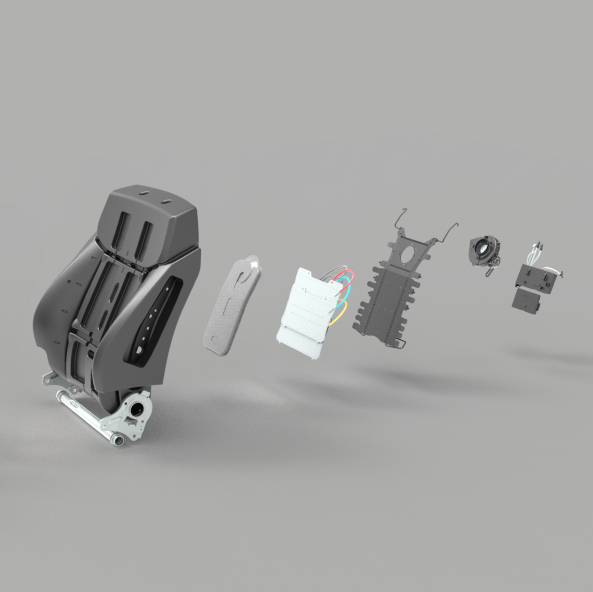

Ein Komfortsystem der nächsten Generation, das Thermo-, Klima-, Lordosenstütz- und Massagefunktionen nahtlos in einem einzigen Modul vereint.

Präzise entwickelt, optimiert diese kompakte Lösung die Integrationszeit, steigert die Fertigungseffizienz und verhindert typische Qualitäts- und Montageprobleme.

Minimale Komplexität;

Maximale Effizienz

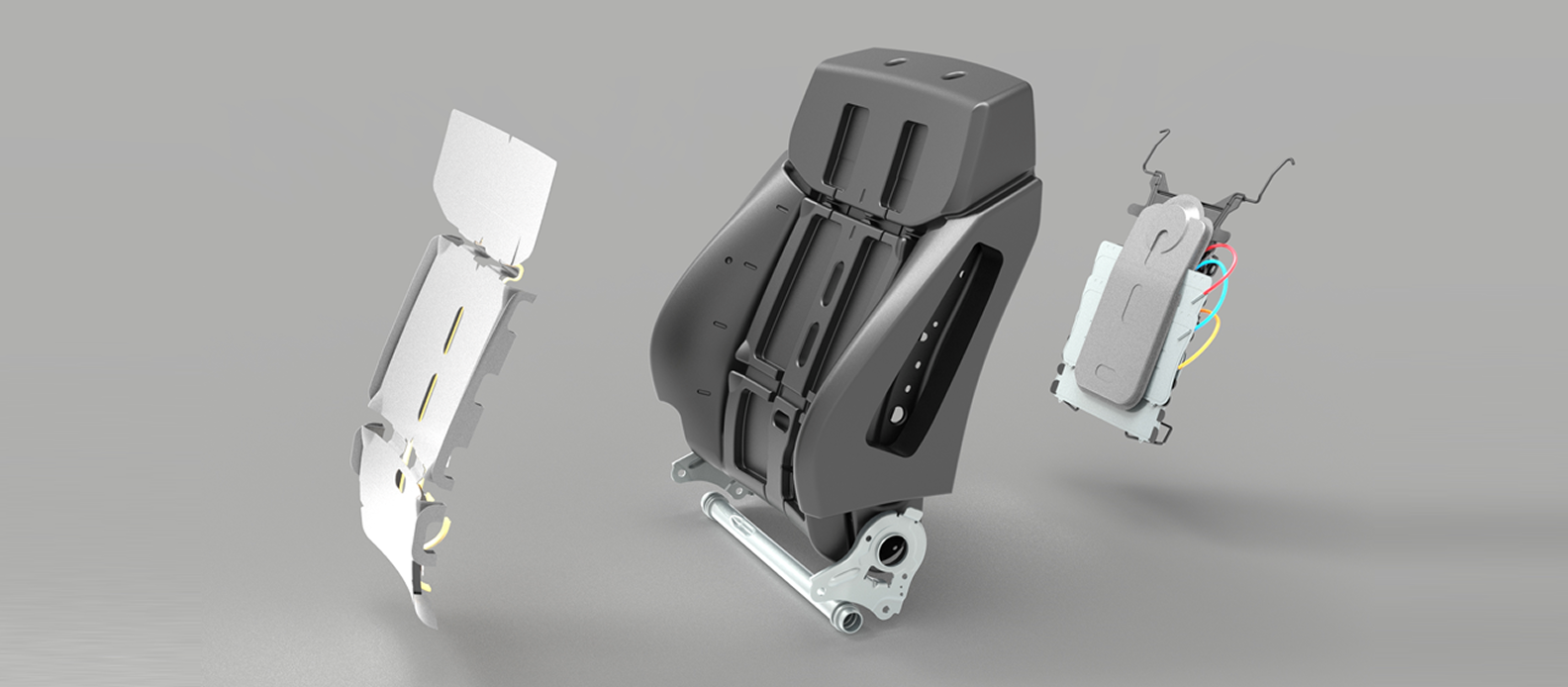

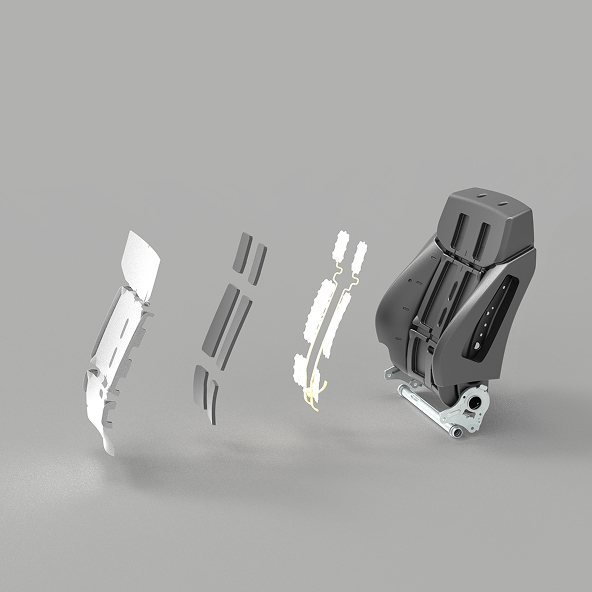

Das vereinheitlichte Trägersystem der Gentherm ComfortScale-Architektur vereint Massage-, Schaum-, Thermo- und Sensorkomponenten in einem schlanken Modul. Diese nahtlose Integration macht separate Luftkammern und Schlauchführungen überflüssig, verkürzt die Montagezeit, minimiert Fehler und steigert gleichzeitig die Gesamtqualität und den Komfort des Sitzes.

Durch die Zusammenführung auf der A-Seite werden Heizmatte, Massageeinheit, Schlauchführung, integrierter Kabelbaum und Sensortechnologien zu einem kompakten Modul kombiniert. Dies vereinfacht die Fertigung und gewährleistet auf jeder Sitzplattform gleichbleibend hohe Qualität und Leistung.

Auf der B-Seite wird durch die Kombination von Belüftung und Lordosenstütze die Installation durch einen effizienten Zweischritt-Ansatz vereinfacht: Zuerst wird der Ventilated-Trim-Bag (VTB) durch ein Band fixiert, anschließend wird die vollständige Belüftung und Lordosenstütze am Sitzrahmen befestigt. Dieser optimierte Ablauf reduziert Montageaufwand und Komplexität.

Durch die Kombination zentraler Komponenten, wie der Hinterfederungsmatte mit dem Lordosensystem, der Luftverteilschicht (VTB), der ECU und dem Twist-and-Lock-Lüfter, wird die B-Seiten-Integration zur schnelleren Montage bei weniger Einzelteilen – für höchsten Komfort, gleichbleibende Qualität und effiziente Produktion.

The Next Degree

Unsere Mitarbeiterinnen und Mitarbeiter sind die treibende Kraft für neue Ideen und die Technologie von morgen.