Battery Performance Solutions

of Battery Performance

For decades, we've been improving vehicle occupant comfort with our heating and cooling solutions. Now, with the rise of electro mobility, another crucial factor comes into play: the vehicle traction battery. It's sensitive to extreme temperatures and requires specialized thermal management to deliver consistent, reliable performance.

Our expert teams specialize in developing solutions to monitor battery temperature and maintain the ideal range for optimal performance. This dedication to battery performance and safety has made us a trusted partner for automotive and battery OEMs around the globe.

Through Innovation

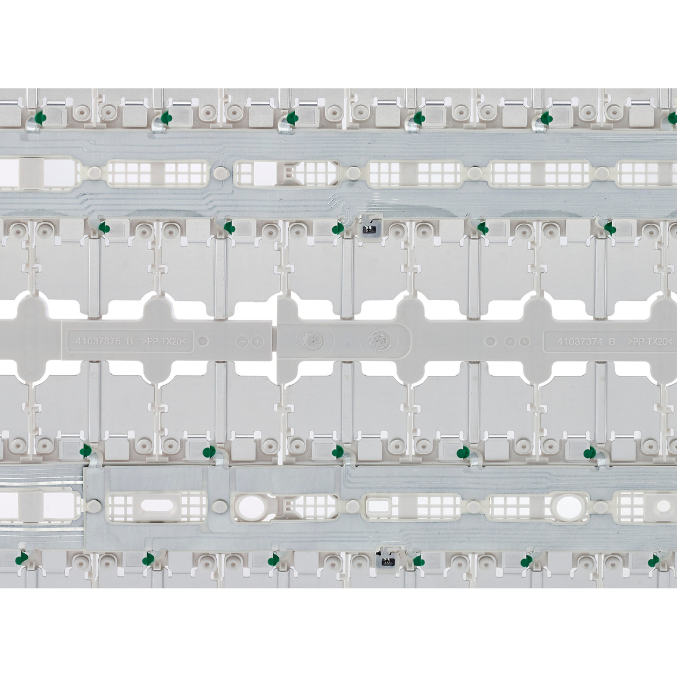

Our flexible printed circuits (FPC) are the result of an innovative and sustainable mechanical structuring process. We have refined this patented technology, becoming an industry pioneer in manufacturing foil conductors for battery cell connecting systems and next-generation direct battery heaters

This groundbreaking technology operates on a single roll-to-roll machine, without the need for chemical etching or ink printing. When compared to traditional copper circuit etching, our process reduces CO₂ equivalent emissions by up to 98% and cuts water consumption by up to 91%. For aluminum circuits, CO₂ emissions are reduced by up to 99%, and water consumption is reduced by up to 98%. These significant reductions have been independently verified by the Fraunhofer Institute for Production Technology IPT.

Management

Our mechanical structuring process creates fast and efficient performing foil heating elements. Gentherm thermal management experts assist in determining the best placement, calculating performance, and designing patterns to improve energy efficiency in direct heating. Thorough simulations are conducted to demonstrate system effectiveness before production begins, ensuring optimal performance.

Gentherm’s blower-based air-cooling solutions are designed for battery systems in mild hybrid EVs, 48V batteries and 12V systems. Our comprehensive system approach delivers a compact design, efficient noise levels, and versatile control interfaces (LIN, PWM, or voltage control) in systems that integrate seamlessly into the unique architecture of each customer.

Thermoelectrics (TE) is a core expertise of ours, primarily utilized in automotive climate-controlled seats. This technology offers a unique advantage, combining both heating and cooling functions within a single device, precisely adapted to real-time needs.

Since 2017, we've extended our TE capabilities to integrate these technologies seamlessly into our battery thermal management system, earning the trust of leading battery and vehicle manufacturers worldwide. Through the application of Peltier elements, our solutions effectively regulate the temperature of the battery's cooling circuit, preventing overheating or under-cooling issues. The thermoelectric effect delivers rapid temperature adjustments that are unmatched by alternatives such as liquid-based systems.

Rapid battery charging is essential for electromobility products, yet traditional systems are not conducive to sustained high-level charging. To overcome this, Gentherm has collaborated with Carrar, an Israeli tech developer specializing in cutting-edge thermal management for electric mobility. Through this partnership, we have introduced direct evaporation liquid technology; a groundbreaking cooling solution that enhances durability and safety concerns across automotive battery systems, powertrains, and electronics.

Technology

Our cell connection systems ensure secure and reliable current transmission between cells, while continuously monitoring vital parameters like temperature and voltage. Specializing in automotive battery cell connections, we're committed to enhancing performance and prolonging energy storage system life.

With over four decades of experience combined with global development and manufacturing capabilities, Gentherm can deliver solutions for virtually any cable and harness requirement. We produce more than 140 million parts per year, which further illustrates the results of our relentless commitment to innovation and quality.

With Us

The Next Degree

Our people inspire ideas that create the technology of tomorrow. Join our team and grow your future with a company committed to innovation and a dynamic, collaborative work environment!